Rail Neer Plants

To enhance passenger amenities, the IRCTC launched Rail Neer, a branded packaged drinking water for the rail commuters. Rail Neer is processed, purified and bottled at state-of-art plants. Completely automatic plant and no manual handling of product water at any stage. IRCTC stands for quality and has a key role in ensuring service and product of the highest quality for the rail passenger as well as visitor to any railway premises. High quality product can only be ensured when production is in-house under full control and supervision of IRCTC.

At present, IRCTC has fourteen operational Rail Neer Plants at Nangloi, Danapur, Palur, Ambernath, Amethi, Parassala, Bilaspur, Sanand, Hapur, Mandideep, Nagpur, Jagiroad, Maneri and Sankrail out of which, Rail Neer Plants at Amethi, Parassala, Nagpur, Sanand, Hapur, Mandideep, Jagiroad, Maneri and Sankrail are under PPP mode, further six more plants are being set up under PPP mode with capital support from IRCTC. Cumulative production capacity of above fourteen Rail Neer Plants is 18.40 lakh bottles per day which will likely be increased to 18.40 lakh bottles per day in FY 2021-22 by setting up six more plants.

Operational Rail Neer Plants:

Nangloi (Delhi)This is the first plant set up by IRCTC in 2003. This is located in West Delhi. The purpose was to supply safe drinking water to important trains originating from New Delhi and Nizammudin. Plant is provided with solar evaporation pond.

This is the second plant set up by IRCTC in 2004. This is located near Patna in Bihar. The purpose was to supply safe drinking water to trains and stations in state of Bihar and Howrah and Sealdah stations in West Bengal.

This is the third plant set up by IRCTC in 2010. This is located near Chennai in Tamil Nadu. The purpose is to supply safe drinking water to trains and stations in the state of Tamilnadu and Karnatka.

The plant has been setup on area of 4500 sq mtrs. The building is constructed in such a manner that there is no need of artificial lighting during day time.

The waste water discharge from Water treatment plant has been reduced to 10%. This is achieved by incorporating concepts of Secondary RO in the Water treatment scheme.

Ambernath (Maharashtra)

This is the fourth plant set up by IRCTC in 2014. This is located near Mumbai in Maharashtra. The purpose is to supply safe drinking water to trains and stations in state of Maharashtra.

This is the fifth plant (first plant under PPP) set up by IRCTC in 2015. This is located near Gauriganj in Uttar Pradesh. The purpose is to supply safe drinking water to trains and stations in state of Uttar Pradesh.

This is the Sixth plant (second plant under PPP) set up by IRCTC in 2016. This is located near Parassala in Trivandrum. The purpose is to supply safe drinking water to trains and stations in state of Kerala.

This is the seventh plant set up by IRCTC in 2017. This is located near Bilaspur in Chhattisgarh. The purpose is to supply safe drinking water to trains and stations in state of Chhattisgarh and Orrisa..

This is the eighth plant set up by IRCTC in 2019. This is located near Masuri Gulawati Road (NCR) at Hapur in Uttar Pradesh. The purpose is to supply safe drinking water to trains and stations in NCR, Western U.P., Haryana, Uttarakhand and Rajasthan

This is the Ninth plant set up by IRCTC in 2019. This is located near Sanand in Ahmadabad. The purpose is to supply safe drinking water to trains and stations in state of Gujarat.

This is the Tenth plant set up by IRCTC in 2019. This is located near Mandideep in Bhopal. The purpose is to supply safe drinking water to trains and stations in state of Madhya Pradesh.

This is the Eleventh plant set up by IRCTC in 2019. This is located at Industrial Area Butibori near Nagpur in Maharashtra. The purpose is to supply safe drinking water to trains and stations in state of Maharashtra.

Jagiroad, Guwahati (Assam)

This is the twelfth Rail Neer Plant set up by IRCTC in 2019. This is located at Amlighat, Dist. - Morigaon, Guwahati in Assam. The purpose is to supply safe drinking water to trains and stations in the state of Assam.

Sankrail, (West Bengal)

This is the thirteen Rail Neer Plant set up by IRCTC in 2020. This is located at Food Park, Phase-III, Sankrail in Howrah (West Bengal). The purpose is to supply safe drinking water to trains and stations in the state of West Bengal..

Jabalpur (Madhya Pradesh)

This is the fourteenth Rail Neer Plant set up by IRCTC in 2020. This is located at Maneri Dist. Mandla (near Jabalpur) in Madhya Pradesh. The purpose is to supply safe drinking water to trains and stations in the state of Madhya Pradesh.

Una (HP)

This is the fifteenth Rail Neer Plant set up by IRCTC in 2021. This is located at Industrial Area Mehatpur Tehsil, Dist. - Una in Himachal Pradesh. The purpose is to supply safe drinking water to trains and stations in the state of Himachal Pradesh.

This is the sixteenth Rail Neer Plant set up by IRCTC in 2023. This is located at Bhusawal Industrial Area, Bhusawal, Dist.- Jalgaon (Maharastra). The purpose is to supply safe drinking water to trains and stations in the state of Maharashtra.

This is the seventeenth Rail Neer Plant set up by IRCTC in 2023. This is located at Plot No. - E-270 & E-271, Industrial Area Kuber (Extn.) Ranpur, Kota, Rajasthan. The purpose is to supply safe drinking water to trains and stations in the state of Maharashtra.

This is the eighteenth Rail Neer Plant set up by IRCTC in 2023. This is located at Plot No. - 13(P) & 14(P), Chhatabar Industrial Area, Bhubaneswar.The purpose is to supply safe drinking water to trains and stations in the state of Maharashtra.

This is the nineteenth Rail Neer Plant set up by IRCTC in 2024. This is located at NTPC Premises, Chipurupalli Village Road, Ravada, Parawada,Visakhapatnam (A.P.) - 531020. The purpose is to supply safe drinking water to trains and stations in the state of Andhra Pradesh.

Manufacturing Process

Water drawn from bore wells is stored in an underground reservoir and pumped to the state of the art water treatment plant.

The plant technology employs eight stages purification processes capable of yielding water quality conforming to BIS standard IS 14543-2004.

- Activated Carbon Filter; Stage 1 & 2 – Stage 1 removes dust, dead microbes, odour/colour and stage 2 is for removing pesticides.

- Auto Softener Unit (ASF) - Hardness of water is removed by ion exchange.

- Ultra Filtration Unit (0.001 micron membrane)–Colloidal, suspended particles and pyrogenic species are filtered out through Ultra Filtration membranes.

- Reverse Osmosis (membrane 0.0001 micron) –All dissolved impurities are removed. Anti scaling agent not used. (All competitors use it to enhances membrane life)

- Marble chip filter- To boost "pH". Exclusive process adopted by Rail Neer.

- Two stage Micron Filters (first membrane 1 micron followed by 0.2 micron)- Impurities with size more than 0.2 micron are filtered out.

- Ultra Violet Sterilizer Unit- UV-light causes change in the genetic material of micro organisms and thus prevents them from reproducing.

- Ozonising Unit- Water comes in contact with ozone gas for final disinfection from the micro organisms. The nascent oxygen is powerful oxidising agent and kills the microbes.

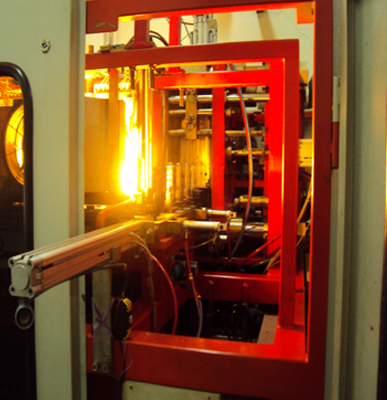

Rail Neer bottles are manufactured with automatic blowing machine (Make –M/s Sidel India Ltd) at plant with high grade resin performs. Preforms are made only with Husky/Kraussmaffei/ASB machine.

Bottle blown at blowing machine travels through air conveyer to automatic Rinsing Filling & Capping machine where bottles are rinsed in inverted position by very high pressure jet and water is completely drained out as bottle is inverted then it get filled with the help of nozzle and passed to capper where the same get capped. The temperature of filling area is kept at 20 degree centigrade and this area is completely enclosed and restricted area and no one except filling operator is allowed to enter the area.

Rail Neer plants at Danapur, Nangloi, Palur and Ambernath are accredited with ISO: 9001- 2008 quality management system certification. Rail Neer Plant at Ambernath is accredited with 22000:2015 certifications. Rail Neer Packaged Drinking Water has been ranked as top performer by "Consumer Voice" Magazine in 2017

Upcoming Rail Neer Plants

| Sr. No. | Location/Plant Name | Production Capacity(Bottles per day) | Status |

|---|---|---|---|

| 1 | Mallavalli (Vijayawada) | 72,000 | Under Construction |

Rail Neer plants at Danapur, Nangloi, Palur and Ambernath are accredited with ISO: 9001- 2008 quality management system certification. Rail Neer Plant at Ambernath is also accredited with 22000:2015 certification. Rail Neer Packaged Drinking Water has been ranked as top performer by "Consumer Voice" Magazine in 2017.

Address and contact details of Rail Neer Plants: West Zone:

Rail Neer Plant Mandideep, Bhopal

| Address | Plot no. 01, Warehousing Complex, Industrial Area, Manideep, Phase-II, Dist. Raisen (MP) |

| Contact No.- | 9004080007 |

| E-mail id | rnpsanand@irctc.com |

Rail Neer Plant Sanand, Ahmedabad

| Address | Plot no. 01, Warehousing Complex, Industrial Area, Manideep, Phase-II, Dist. Raisen (MP) |

| Contact No.- | 9004080007 |

| E-mail id | rnpsanand@irctc.com |

Rail Neer Plant, Ambernath

| Address | GIP Dam, Near additional MIDC, Post Anand Nagar, Ambernath (East), Dist. Thane, Maharashtra-421506 |

| Contact No.- | 9004082752 |

| E-mail id | ambernath.rnp@irctc.com |

Rail Neer Plant, Nagpur

| Address | D-53, MIDC Buti Bori Industrial Area, Dist. Nagpur |

| Contact No.- | 011-42581132 |

| E-mail id | rnpnagpur@irctc.com |

Rail Neer Plant, Bhusawal

| Address | Plot No. F-20, Bhusawal Industrial Area, Bhusawal, Dist.� Jalgaon (Maharastra) |

| Status | Under Construction |

Rail Neer Plant, Jabalpur

| Address | Plot No. 11, Sec- E, IGC Maneri Dist. Mandla (Jabalpur) |

| Contact No. | 9831042147 |

| E-mail id - | rnpmaneri@irctc.com |

East Zone:

Rail Neer Plant, Sankrail

| Address | FP3/8, Food Park, Phase-III, Sankrail |

| Contact No. | 9831042147 |

| E-mail id - | rnpsankrail@irctc.com |

Rail Neer Plant, Jagi Road (near Guwahati)

| Address | Village Borkhal under Uttar khola Mouza, Amlighat, Dist.Morigaon,Guwahati (Assam) |

| Contact No. | 9435060250 |

| E-mail id - | rnpjagiroad@irctc.com |

Rail Neer Plant, Danapur

| Address | Loco Colony, South R.P.F. Barracks, Khagul, Danapur-801105 (Bihar) |

| Contact No - | 0612-3295150 |

| E-mail id - | railneerdanapur@irctc.com |

North Zone:

Rail Neer Plant, Nangloi

| Address | Northern Railway�s Wireless Station Area, Opp. Nangloi Bus Depot, Rohtak Road, Nangloi, Delhi-110041 |

| Contat No- | 011-25949774-75 |

| Email Id- | railneernangloi@irctc.com |

Rail Neer Plant, Hapur

| Address | I-2, Phase-III, Industrial Area, Massori Gulavathi Road, Hapur (U.P.) |

| Contat No- | 9717640700 |

| Email Id- | rnphapur@irctc.com |

Rail Neer Plant, Mehatpur, Dist.-Una

| Address | Plot no. - 5A(1), Industrial Area Mehatpur, Dist. - Una |

| Contact no. | 9717640700 |

| Email Id- | rnpuna@irctc.com |

Rail Neer Plant, Amethi

| Address | Plot No. C11 & 12, UPSIDC Industrial Area, Takaria Gauriganj, Distt. Amethi |

| Contact no- | 9839358105 |

| Email Id- | railneerplantamethi@irctc.com |

South Central Zone:

Rail Neer Plant, Bilaspur

| Address | Plot No. 22/23, Sector-B, Sirigitti Industrial Area, Dist. Bilaspur, (CG)- 495004 |

| Contat No- | 97176492215 |

| Email Id- | railneerbilaspur@irctc.com |

South Zone:

Rail Neer Plant,NTPC

| Address | Super Thermal Power Station premises located at Simhadri, Dist. Visakhapatnam, Andhra Pradesh - 531020 |

| Status- | Under Construction |

South Zone:

Rail Neer Plant, Bhubaneswar

| Address | Plot No.- 13(P) & 14 (P), Chhatabar Industrial Area, Bhubaneswar- 752054 |

| Status- | Under Construction |

South Zone:

Rail Neer Plant, Palur

| Address | Station, Taluk - Chenagalpattu, Distt. Kanchipuram, Tamilnadu |

| Contat No- | 044-27437007 |

| Email Id- | railneerpalur@irctc.com |

Rail Neer Plant, Parassala

| Address | Railway Yard, Near Parassala Railway Station, Kerala-695502 |

| Contat No- | 0471-2203355 |

| Email Id- | railneerplantparassala@irctc.com |

Rail Neer Plant, Vijayawada

| Address | Plot no-9/21, Model Industrial Park, Dist. Krishan,Mallavali ,Vijaywada(AP). |

| Status | Under Construction |

Innovations & Initiatives